Sourcing air fryers but worried about fake factories? Unverified suppliers can cause costly delays and quality issues, damaging your brand’s reputation. Here’s how we ensure complete partner transparency.

To verify a Chinese air fryer factory, you must systematically check their business license, request key product and system certifications like ISO 9001 and CE/ETL, confirm document authenticity, and assess real manufacturing capabilities through video tours or third-party audits before placing an order.

Verifying a supplier goes beyond just looking at their website. It requires a structured approach to ensure you partner with a legitimate and capable manufacturer. Let’s break down the essential steps to protect your investment.

What certificates or licenses should I request to confirm production qualifications?

Are you overwhelmed by the number of documents a supplier can send? Focusing on the wrong paperwork wastes time and leaves your business exposed to unqualified partners.

Always request a valid Business License to confirm legal status and manufacturing scope. For quality and safety, ask for an ISO 9001 certificate for their quality management system and product-specific certifications like CE, RoHS, UL, or ETL that match your target market’s requirements.

When we work with new clients, we find that providing clear documentation upfront builds immediate trust. The documents you request act as the first layer of your due diligence. A professional factory will have these readily available and will not hesitate to share them.

Core Legal and System Documents

The first step is to confirm you are dealing with a legally registered manufacturer, not just a trading company with no production assets.

- Business License : This is the most fundamental document. Ask for a clear, current scan. The business scope section is critical. It should explicitly state "production" or "manufacturing" of home appliances or electronic products. If it only lists "sales," "trade," or "consulting," they are likely a middleman.

- ISO 9001 Certificate1: This demonstrates that the factory has an established Quality Management System (QMS). It indicates a commitment to consistent processes, from material sourcing to final inspection. A factory without it may have inconsistent, ad-hoc quality control, which is a major risk for buyers.

- Social Compliance Audits (BSCI/Sedex)2: While not a direct measure of production quality, reports from audits like BSCI (Business Social Compliance Initiative) or Sedex show the factory’s commitment to ethical labor practices. This is increasingly important for brand reputation in Western markets.

Essential Product-Specific Certifications

These certificates prove that the air fryer model you intend to purchase has been tested and complies with the safety and material standards of your destination market. The name on the certificate should match the factory’s name on the Business License.

| Certificate | Target Market | What It Verifies |

|---|---|---|

| CE Mark3 | European Union (EU) | The product meets EU safety, health, and environmental protection requirements. Must be supported by a Declaration of Conformity (DoC) and technical test reports. |

| RoHS4 | European Union (EU) | Restricts the use of specific hazardous materials found in electrical and electronic products. |

| UL/ETL | North America (USA/Canada) | The product complies with North American electrical safety standards. These marks are issued by certified independent testing labs. |

| FCC | United States (USA) | The product’s electronic emissions do not interfere with other electronic devices. This is crucial for appliances with digital controls. |

Always demand the full test report, not just the certificate summary. A legitimate factory will provide this.

How can I check the factory’s compliance with industry standards?

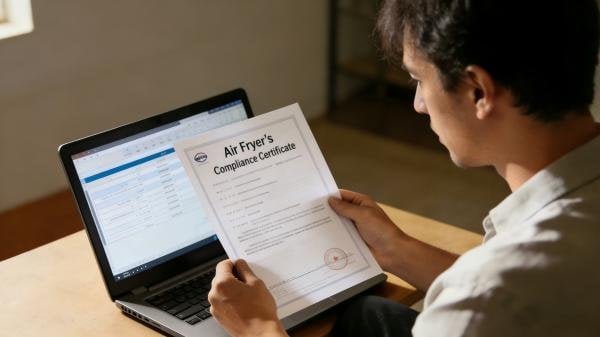

Receiving a stack of certificates feels reassuring, but how do you know they are real? Forged or expired documents are a common risk when sourcing from new suppliers.

Verify certificates by checking the issuing body’s public online database using the certificate number. For product safety reports like CE or UL, contact the accredited lab shown on the report directly to confirm its authenticity and scope. Be skeptical of blurry scans or mismatched company names.

Verifying documents is a non-negotiable step in our own supply chain management. It’s a simple check that can prevent significant problems down the road. A common red flag is a CE certificate that is just a "self-declaration" without any supporting test report from a recognized third-party laboratory. While technically allowed in some cases, it offers very little assurance of actual compliance. A serious manufacturer invests in proper testing.

A Step-by-Step Verification Guide

Don’t just take the supplier’s word for it. Use these methods to independently verify the documents you receive.

- Verifying ISO 90015: Look for the name of the certification body on the certificate (e.g., SGS, TUV, Intertek). Go to their website and search for their certified client directory. You can usually input the certificate number or company name to confirm its status and validity period. You can also check the IAF (International Accreditation Forum) database.

- Verifying Product Certificates (CE, UL, ETL)6: The test report is more important than the certificate. It contains the name and address of the laboratory that performed the tests. A quick Google search will tell you if the lab is reputable and accredited. For UL/ETL, you can use their public online directories to look up the file number listed on the product’s marking.

- Cross-Referencing Company Names7: This is a simple but powerful check. Does the company name on the Business License, the ISO 9001 certificate, the product test reports, and your Proforma Invoice (PI) all match perfectly? Any discrepancies could mean you are dealing with a trading company using a different factory’s credentials.

Common Red Flags in Documentation

| Red Flag | What It Might Mean | How to React |

|---|---|---|

| Blurry or Cropped Scans | The supplier may be hiding information, such as an expiration date or a different company name. | Request a high-resolution, complete scan. If they refuse, it’s a major warning sign. |

| Mismatched Company Names | The supplier is likely a trading company, not the manufacturer. The actual factory is unknown. | Ask for a clear explanation. If they are a trader, they should be transparent about it. |

| Expired Certificates8 | The factory’s quality system or product compliance is no longer certified and may not be maintained. | Ask if they are in the process of recertification and request proof. Do not proceed until valid certificates are provided. |

| "Self-Declared" CE Mark | The factory has not invested in independent testing, and the product may not actually meet EU standards. | Insist on a full test report from a reputable, accredited third-party lab. |

What audits or inspections can I conduct to verify qualifications?

Documents prove a factory is legal, but they don’t prove it can actually build your product well. How can you see their real capabilities without visiting in person?

Arrange a live video factory tour to see the assembly lines, testing equipment, and warehouse in real-time. For larger orders or long-term partnerships, commissioning a third-party factory audit provides an independent, in-depth assessment of their production capacity and quality systems.

In our experience, a factory’s willingness to accommodate these requests speaks volumes. We regularly host video tours for clients, showing them our specific production lines, from metal stamping and coating to final assembly and packaging. A genuine manufacturer is proud to show off their operations. If a supplier makes excuses, claims their factory is "secret," or only shows you a showroom, be cautious. They might be hiding the fact that they are just a trading office.

The Power of a Virtual Factory Tour

A live video call is a quick, cost-effective way to get a feel for the factory. During the call, direct your contact to show you specific areas.

- Assembly Lines9: Are they organized? Do workers have clear instructions? Look for signs of a structured process, not a chaotic workshop.

- Testing Stations: A dedicated air fryer factory will have specific equipment to test electrical safety (hi-pot test, ground continuity), performance (temperature accuracy, airflow), and durability (switch life, door hinge tests). Ask to see these in operation.

- Warehouse: Check their raw material storage and finished goods areas. A well-organized warehouse suggests a systematic approach to production management.

- Real People: Are there actually workers on the line? Empty factories during business hours are a huge red flag.

When to Use a Third-Party Audit10

For significant orders, a professional audit is a wise investment. An auditor will spend a full day at the factory and provide a detailed report covering:

| Audit Section | Key Checks | Why It Matters |

|---|---|---|

| Factory Profile | Verifies legal status, ownership, and size. | Confirms the basic information you were given is accurate. |

| Manpower | Number of workers in R&D, QC, and production. | Assesses if they have enough skilled staff to handle your order and maintain quality. |

| Production Capacity11 | Reviews machinery, line output, and historical production records. | Determines if they can meet your volume and lead time requirements without subcontracting. |

| Quality Control System12 | Checks for incoming material inspection (IQC), in-process QC (IPQC), and final QC (FQC) procedures. | Reveals the maturity of their quality system and their ability to catch defects early. |

| Certifications & Records | Independently verifies all documents on-site. | Provides a final, impartial confirmation of all the paperwork you have collected. |

Hiring an auditor from a company like QIMA, Bureau Veritas, or SGS typically costs a few hundred dollars but can save you thousands by avoiding a disastrous partnership.

How do I handle factories with incomplete documentation?

You’ve found a factory with a great product and price, but their paperwork is a mess. Should you walk away immediately, or is there a way to move forward?

If documentation is incomplete, first clarify why. If they are a new factory or in recertification, you can proceed with caution by using a third-party audit to verify capabilities directly. However, if they are evasive or refuse to provide key documents, it is best to disengage.

This is a judgment call that depends on the specific situation. Sometimes, a promising new factory is still in the process of getting its ISO 9001 certification. Or perhaps their ETL certificate for a new model is pending. In these cases, transparency is key. We have worked with clients in this scenario by providing a clear timeline for certification and offering additional on-site inspections at our cost to build confidence.

However, a flat-out refusal to provide a business license or a valid safety test report for a product they claim is "ready to ship" is a deal-breaker. This often indicates they are not the manufacturer or that the product is not compliant.

A Framework for Decision-Making

When faced with incomplete documentation, use this framework to decide your next steps:

-

Ask "Why?": Directly and politely ask the supplier why the document is missing. Is the certificate expired and being renewed? Is it a new product still undergoing testing? A legitimate reason will come with a clear explanation and a timeline for resolution. Evasiveness is a bad sign.

-

Assess the Missing Document’s Importance: A missing BSCI audit13 is less critical than a missing UL safety certificate for the US market. A factory can operate without a social audit, but you cannot legally sell a product without the required safety certifications. Prioritize non-negotiable documents.

-

Increase Your Own Verification: If you decide to proceed, you must compensate for the missing information.

- No ISO 900114? Commission a thorough factory audit focused heavily on their quality management system.

- Pending Product Certificate? Get a sample from the production batch and send it to your own trusted lab for testing. This gives you independent confirmation.

- Unclear if they are a factory? A virtual tour is a minimum requirement. An on-site audit is better.

-

Use Your Contract: If the supplier promises a certificate will be ready by a certain date, make this a legally binding condition in your purchase contract. Include a clause that allows you to cancel the order or receive a penalty payment if they fail to deliver the promised documentation on time.

Never skip due diligence. The initial excitement of a good price can quickly turn into a nightmare of quality issues, shipping delays, or customs rejection.

Conclusion

Verifying a factory’s qualifications is a crucial, multi-step process. By systematically checking documents, verifying their authenticity, and inspecting real capabilities, you can confidently partner with reliable Chinese air fryer manufacturers.

-

Understanding ISO 9001 can help you assess a manufacturer’s quality management practices, ensuring reliable products. ↩

-

Exploring social compliance audits reveals how manufacturers uphold ethical labor practices, crucial for brand reputation. ↩

-

Learn about the CE Mark to ensure your products meet EU safety standards, protecting consumers and your brand. ↩

-

Understanding RoHS helps ensure your products comply with environmental regulations, enhancing marketability in the EU. ↩

-

Understanding the verification process for ISO 9001 can help ensure your suppliers meet quality standards. ↩

-

Learn how to effectively verify product certificates to ensure safety and compliance in your purchases. ↩

-

Discover the significance of cross-referencing company names to avoid potential fraud in supplier relationships. ↩

-

Find out the necessary steps to take when faced with expired certificates to protect your business interests. ↩

-

Explore this link to learn how organized assembly lines enhance efficiency and productivity in manufacturing. ↩

-

Learn how third-party audits can provide unbiased insights and protect your investment in manufacturing. ↩

-

Understanding production capacity can help you assess a factory’s ability to meet your demands. ↩

-

Discover the importance of quality control systems in ensuring product quality and reducing defects. ↩

-

Understanding BSCI audits can help you prioritize essential documents and ensure compliance in your supply chain. ↩

-

Exploring ISO 9001 will enhance your knowledge of quality management systems, crucial for maintaining product standards. ↩