Are you worried your imported air fryers can’t handle the heat? Component failure leads to returns and damages your brand. We focus on key high-temperature specs to ensure product safety.

To assess high-temperature components in Chinese air fryers, you must verify material certifications for plastics and metals, request specific performance test reports like heat-cycle tests, and confirm compliance with safety standards such as UL or EN through third-party inspections before shipment.

Assessing these critical parts is not as complex as it seems. Let’s break down the key areas you need to focus on to ensure you are sourcing durable and safe products.

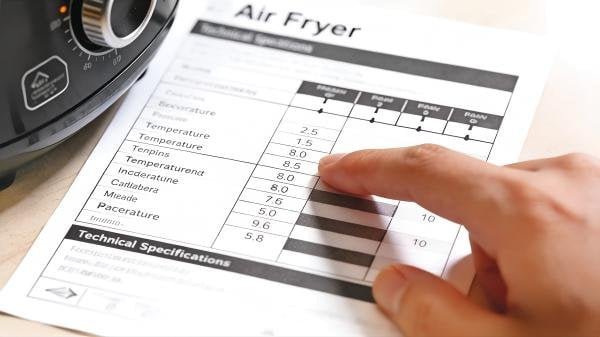

What specifications should I review for high-temperature components?

Struggling to make sense of technical data sheets? Overlooking a single specification for a heating element or plastic housing can lead to product failure and unhappy customers down the line.

You should review specifications for the heating element, internal wiring, plastic housing, and non-stick coatings. Ensure heating elements are stainless steel, plastics are rated for temperatures above 120°C, and coatings are certified PFOA-free and can pass durability tests.

When we build air fryers, our primary focus is on how materials behave under stress. The internal temperature of an air fryer can exceed 200°C (400°F), so every component in the cooking chamber must be up to the task. Simply accepting a supplier’s claim of "high-temperature resistance" is not enough. You need to dive into the specifics.

Key Component Specifications

Start with the core components. The heating tube, typically made from stainless steel like SUS304, needs to resist corrosion and thermal stress. The plastic parts, especially the main housing and drawer handle, are equally critical. They must be made from materials like PP (Polypropylene) or PBT (Polybutylene terephthalate) with a high Heat Deflection Temperature1 (HDT), ideally above 120°C. This prevents warping, melting, or releasing harmful fumes during operation.

The non-stick coating inside the basket is another major point of concern. Look for certifications that prove it is free from harmful chemicals like PFOA and PFAS. A quality coating should also withstand physical and chemical stress without peeling or chipping.

Here is a table outlining the essential specifications to check:

| Component | Material/Specification Requirement | Why It Matters |

|---|---|---|

| Heating Element | Stainless Steel (SUS304 or better) | Resists rust and high-heat degradation. |

| Plastic Housing/Parts | PP or PBT with HDT > 120°C | Prevents melting, warping, and releasing toxic fumes. |

| Internal Wiring | Silicone-insulated copper wires | Withstands high internal temperatures without melting. |

| Non-Stick Coating2 | Certified PFOA/PFAS-free; passes 1,000-cycle abrasion test | Ensures food safety and long-term durability. |

By systematically reviewing these specifications on the product data sheet, you create a baseline for quality and can quickly filter out suppliers who use substandard materials.

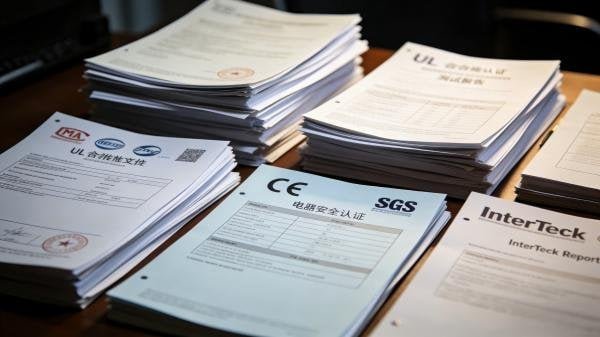

How can I request test reports or certifications from suppliers?

Finding a supplier is easy, but how do you verify their claims? Without proof, you’re buying based on trust alone, which can be a costly mistake in manufacturing.

Simply ask your supplier directly for copies of material certificates, third-party lab test reports, and compliance documents for standards like UL, CE, or GB. Specify that you need reports for the exact components used in your model, not generic company-wide certifications.

In our experience exporting to markets like the US and Europe, providing documentation is a standard part of business. A reputable supplier will have these documents ready. If a supplier is hesitant or unable to provide them, it’s a major red flag. Vague assurances are not a substitute for hard data.

The Right Documents to Ask For

When you contact a supplier, be specific. Don’t just ask for "certifications." Instead, request documents that validate the quality of high-temperature components.

- Material Safety Data Sheets (MSDS)3: For all plastic components and coatings. This document details the chemical properties and safety information, including temperature resistance.

- RoHS and REACH Certificates4: These EU-based directives restrict the use of specific hazardous substances. They are a good indicator of material safety, especially for electronics and coatings.

- Third-Party Test Reports5: Ask for reports from accredited labs like SGS, Intertek, or TÜV. These should cover performance tests like heat-cycling, temperature accuracy, and coating adhesion tests.

- Compliance Certificates6: Depending on your target market, you’ll need certificates like UL 60335 (for the US), EN 60335 (for the EU), or GB 4706 (for China). These confirm the entire appliance meets electrical safety standards.

Here’s a checklist you can use when communicating with suppliers:

| Document Type | What to Look For | Red Flag |

|---|---|---|

| Material Certificates | Specific grade of steel (e.g., SUS304), plastic (e.g., PP) | Generic, undated, or from an unknown source. |

| Coating Test Report | PFOA/PFAS-free statement, adhesion/abrasion test results. | No mention of specific chemicals or durability tests. |

| Appliance Safety Certificate | Model number matches your product; issued by an accredited lab. | Expired certificate or for a different model. |

Being prepared with these requests shows the supplier that you are a serious and knowledgeable buyer. It sets a professional tone for your business relationship and ensures you get the quality you are paying for.

What questions should I ask about material selection and durability?

You have the spec sheets, but what do they really mean for long-term use? Asking the right follow-up questions can reveal a supplier’s true commitment to quality versus just meeting minimum standards.

Ask suppliers why they chose specific materials for high-heat areas, what their testing protocol is for long-term durability, and what the expected lifespan of components like the heating element and motor is under continuous use. Inquire about their quality control process.

When we develop a new air fryer model, material selection is a process of balancing cost, performance, and longevity. A cheap material might pass initial tests but fail after six months of use. Your questions should probe into this logic. Don’t be afraid to sound like you’re challenging them; a good partner will appreciate your diligence.

Probing for Deeper Insights

Go beyond the surface level. Your goal is to understand the "why" behind their engineering choices.

- "Why did you choose PBT7 for the basket holder instead of a cheaper PP?" This question forces them to justify their material choices. A good answer would involve citing PBT7‘s superior heat and chemical resistance, which improves durability.

- "What is your standard procedure for life testing8 the fan motor?" The motor operates in a hot environment. Ask for details on their 500-hour or 1,000-hour continuous run tests. What is the acceptable performance decay? (A good standard is <10% speed reduction).

- "How do you test the durability of the non-stick coating?" A simple "it’s non-stick" isn’t enough. Ask if they perform cross-hatch adhesion tests or abrasion tests (e.g., with a steel wool pad for a set number of cycles).

- "What is your in-process QC checklist for high-temperature components?" This gives you insight into their production-line quality control3. Do they test components before assembly?

Here is a sample list of questions to guide your conversation:

| Topic Area | Sample Question | Desired Answer |

|---|---|---|

| Material Choice | Why was this specific grade of plastic/metal chosen for this part? | Cites specific properties like HDT, tensile strength, or corrosion resistance. |

| Durability Testing | Can you describe your heat-cycle test? (e.g., 30 mins on, 15 mins off for 500 cycles) | Provides clear parameters and pass/fail criteria for the test. |

| Component Lifespan | What is the warrantied lifespan of the heating element and motor in hours? | A specific number (e.g., 2,000 hours) backed by life-test data. |

| Quality Control | How do you ensure consistency in materials from batch to batch? | Mentions incoming quality control3 (IQC) and supplier audits. |

These questions transform you from a passive buyer into an active partner in quality assurance. They help build a relationship based on transparency and a shared commitment to a high-quality final product.

How do I compare component quality across different models?

You’re evaluating three different air fryers that look similar. How do you determine which one uses superior high-temperature components when all claim to be "high quality"?

Create a comparison scorecard. List critical components like the heating tube, internal plastics, and coating. For each model, fill in the specific material grades, temperature ratings, and any relevant certifications. This objective data makes it easy to identify the superior model.

When our clients compare our models against competitors, we encourage them to look at the details. A slightly cheaper unit often cuts corners on things you can’t see, like using a lower-grade plastic that might become brittle or using a coating that peels after a few months. A side-by-side comparison makes these differences obvious.

Building Your Comparison Matrix

Your goal is to move from subjective feelings to objective facts. A simple table or spreadsheet is the best tool for this. List the models you are considering in the columns and the key quality indicators in the rows.

Key Comparison Points:

- Heating Element9: Is it SUS304 or a lower-grade stainless steel? A higher grade means better corrosion resistance.

- Internal Plastics: Note the material type (PBT, PP) and its Heat Deflection Temperature (HDT). A higher HDT is always better.

- Coating: Is it a branded coating (like Teflon) or a generic one? Does it have PFOA-free certification? Does the supplier provide abrasion test results?

- Motor: Is there information on the motor’s bearing type (e.g., ball bearing vs. sleeve bearing)? Ball bearings typically last longer in high-heat environments.

- Certifications10: Does Model A have a UL certification while Model B only has a self-declared CE mark? The UL certification is generally more rigorous.

After you gather this data from spec sheets and supplier communications, you can assign a simple score (e.g., 1-5) to each component for each model. The model with the highest total score is likely the one with the best overall component quality. This methodical approach removes guesswork and helps you justify your sourcing decision with concrete evidence. It ensures you invest in a product that will uphold your brand’s reputation for quality and safety.

Conclusion

Assessing high-temperature components is crucial for sourcing safe, reliable air fryers. By reviewing specs, requesting reports, asking smart questions, and comparing models methodically, you can confidently choose a quality product.

-

Learn about Heat Deflection Temperature to ensure the plastic components in your products can withstand high temperatures without failure. ↩

-

Explore this link to understand the health and safety advantages of using PFOA/PFAS-free non-stick coatings in kitchenware. ↩

-

Understanding MSDS is crucial for ensuring safety and compliance in materials used in manufacturing. ↩ ↩ ↩

-

These certificates are vital for ensuring that products meet safety standards and regulations in the EU. ↩

-

Third-party testing ensures unbiased verification of product performance and safety, enhancing trust. ↩

-

Explore the advantages of PBT, including its heat and chemical resistance, which enhance product durability. ↩

-

Understand how life testing contributes to product longevity and customer satisfaction. ↩ ↩

-

Discover essential quality control practices that can improve product consistency and reduce defects. ↩

-

Understanding the benefits of SUS304 can help you choose a more durable and corrosion-resistant heating element. ↩

-

Exploring certification differences can ensure you select a product that meets rigorous safety standards. ↩