Frustrated when your air fryer specifications are lost in translation? These costly errors delay production and hurt your profits. We see it happen, but there are straightforward ways to prevent it.

To handle misunderstandings, use simple English, provide visual aids, and confirm all details in writing. Create bilingual documents for critical specifications. Use platforms like WeChat for quick questions but always follow up with a formal email to document the agreement and ensure clarity.

Miscommunication can turn a promising partnership into a liability. Let’s break down the proven strategies we use with our clients to ensure every air fryer order is executed flawlessly.

What Strategies Help Prevent Misunderstandings in Supplier Communication?

Are you tired of receiving air fryer samples that don’t match your request? Proactive communication is the solution. From our assembly lines, we know that prevention is always better than correction.

The best strategies are simplifying language, providing detailed technical specifications, and using visual aids. Avoid idioms and complex sentences. A comprehensive Request for Quotation (RFQ) with clear measurements, materials, and packaging requirements is essential to prevent ambiguity before production even begins.

Preventing misunderstandings starts long before an order is placed. It begins with how you frame your requirements. In our experience, the most successful clients are those who prioritize clarity above all else. Vague instructions are the primary cause of production errors. Instead of saying "make it high quality," you should specify the exact material grade, the thickness of the plastic, and the brand of the heating element.

Use Simple and Direct Language

English is not the first language for most Chinese suppliers. Complex sentences, industry jargon, and cultural idioms can easily be misinterpreted. Break down your instructions into short, simple sentences. For example, instead of writing, "I’d like you to expedite the tooling process and circle back with a revised T1 sample delivery date," try this:

- Please finish the new mold quickly.

- What is the new delivery date for the first sample?

Always confirm their understanding by asking, "Do you understand these instructions?" This simple check can save weeks of rework.

Create Detailed Specification Documents

A detailed document is your single source of truth. Before we start any new air fryer project, we require a complete tech pack from our clients. This document leaves no room for guessing.

Your specification sheet should include:

- Product Dimensions: Height, width, depth, and weight.

- Materials: Specific types of plastic (e.g., PP, ABS), steel grade for internal components, and non-stick coating specifications.

- Color Codes: Use Pantone color codes1 for all parts.

- Functionality: Wattage, temperature range, timer settings, and pre-set cooking programs.

- Packaging: Box dimensions, cardboard thickness, printing details, and drop-test requirements.

Here is a table comparing clear vs. unclear instructions:

| Unclear Instruction | Clear Instruction | Why It’s Better |

|---|---|---|

| "Use good material." | "Use food-grade 304 stainless steel2 for the basket." | Specifies exact material, leaving no room for interpretation. |

| "Make the logo bigger." | "Increase the logo size to 35mm wide on the front panel." | Provides a precise measurement and location. |

| "Fast shipping." | "Ship via sea freight to Port of Long Beach. Ready by May 30." | Defines the method, destination, and deadline. |

By being extremely specific from the start, you eliminate ambiguity and ensure the supplier knows exactly what to build.

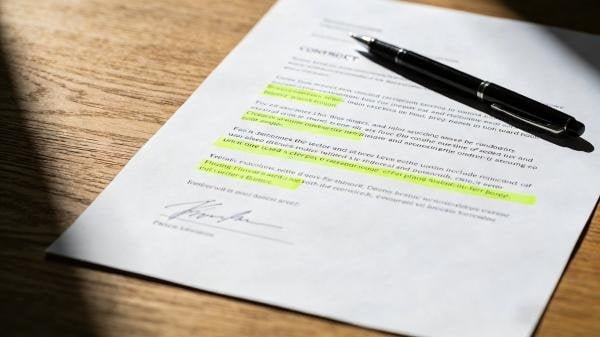

How Can I Clarify and Document Important Agreements?

Have you ever had a supplier agree to a change verbally, only to forget it later? Relying on memory is a recipe for disaster. On our side, documented agreements are non-negotiable for production changes.

Clarify agreements by summarizing them in a follow-up email after every call or meeting. Use bilingual contracts for major terms like price, delivery dates, and quality standards. Maintain a shared document tracking all changes, approvals, and key decisions for both parties to reference.

Verbal communication is great for building rapport, but it is terrible for creating a reliable record. Cultural nuances can also create situations where a supplier says "yes" to be polite, even if they don’t fully understand or agree. That’s why every single important detail must be put in writing. This practice protects both you and the supplier. When a question arises weeks later, you have a clear record to refer back to, eliminating "he said, she said" disputes.

The Power of the Follow-Up Email

After every single conversation—whether on the phone, via video call, or on WeChat—send a summary email. This email should be simple and clear.

- Start with a clear subject line, like: "Summary of Our Call on May 15: Air Fryer Model A8."

- Use bullet points to list the key decisions and action items.

- Assign responsibility for each action item (e.g., "Supplier to send new drawings by May 17").

- End the email with a clear request for confirmation, such as, "Please reply to this email to confirm that you agree with this summary."

This creates a paper trail that is indisputable. When we receive such emails, it helps our project managers align our internal teams, from engineering to the production line.

Use a Documentation Checklist

A systematic approach ensures nothing falls through the cracks. We advise our clients to use a checklist to track all critical documentation for their air fryer orders.

| Document Type | Purpose | Status (Example) |

|---|---|---|

| Product Spec Sheet | Defines all technical details and materials. | Finalized & Confirmed |

| Purchase Order (PO) | Formalizes the order quantity, price, and terms. | Signed & Returned |

| Bilingual Contract | Legally binding agreement on key commercial terms. | Signed by Both Parties |

| Quality Control Checklist | Lists all inspection points for production and final checks. | Approved |

| Shipping Marks | Details for carton printing (logo, model, address). | Confirmed |

This organized approach ensures that both sides are working from the same set of instructions, dramatically reducing the risk of errors related to misremembered details.

What Tools or Platforms Improve Communication Accuracy?

Are your messages getting lost across different apps and email threads? Using the right tool for the right task is crucial. We use a mix of platforms to keep communication with our partners efficient and clear.

For optimal accuracy, use email for formal agreements, contracts, and specifications that require a paper trail. Use messaging apps like WeChat for quick, informal questions and sharing photos from the factory floor. Video calls are best for design reviews and complex problem-solving.

Choosing the right communication tool is about matching the medium to the message. A quick question about production status doesn’t need a formal email, but a change to the product’s motor specification absolutely does. Using a blended approach ensures you are both efficient and accurate. When we onboard a new B2B client, we establish these communication channels early on. We clarify what tool to use for which type of query, which sets a clear protocol and prevents confusion down the line.

Matching the Tool to the Task

Different situations call for different tools. A common mistake is using an informal tool for a formal agreement. For instance, agreeing to a price change on WeChat without a follow-up email is risky. The message can get lost, and it holds less weight than a formal document. We recommend a structured approach.

Here’s a simple guide we share with our partners:

| Communication Tool | Best For | Pros | Cons |

|---|---|---|---|

| Formal agreements, POs, contracts, spec changes. | Creates a searchable record; formal. | Slower response time. | |

| WeChat/WhatsApp | Quick questions, sharing production photos, informal updates. | Instant response; easy to use. | Unofficial; messages can get lost. |

| Video Calls (Zoom/Skype) | Design reviews, problem-solving, factory tours. | Face-to-face interaction; builds rapport. | Requires scheduling; language barriers can be more obvious. |

By defining how each tool should be used, you create a system that is both fast and reliable. For example, a client might send us a picture on WeChat of a minor cosmetic detail they want to adjust. We can quickly confirm it and then ask them to send a formal email to update the official spec sheet.

Leveraging Visual Communication

A picture is truly worth a thousand words, especially when crossing language barriers. Instead of trying to describe a complex shape or a specific shade of blue, send a picture. Mark up photos and drawings with arrows, circles, and clear notes to highlight exactly what you mean. When we are developing a new air fryer design, our engineers exchange dozens of annotated CAD drawings and photos with the client’s team. This visual back-and-forth is far more effective than relying on text alone. It helps us catch potential design flaws early and ensures the final product is exactly as envisioned.

How Do I Resolve Disputes Caused by Miscommunication?

What happens when, despite your best efforts, a misunderstanding leads to a dispute? Remaining calm and strategic is key. In our business, how you handle a dispute defines the long-term health of the partnership.

To resolve disputes, first refer back to your written documentation to identify the source of the misunderstanding. Approach the supplier calmly and without placing blame, focusing on a solution. If needed, escalate the issue to a manager or factory owner who has decision-making power.

Disputes are an unfortunate but sometimes unavoidable part of business. The key is to approach them as a problem to be solved together, not a battle to be won. In Chinese business culture, the concept of "face" (面子, miànzi) is extremely important. Publicly blaming or embarrassing your supplier will likely damage the relationship and make them less willing to help. Instead, present the issue as a mutual challenge. For example, you could say, "There seems to be a misunderstanding about the basket coating. Let’s look at the specification sheet together and find a way to fix it."

A Step-by-Step Resolution Process

When a problem arises with an air fryer shipment, a structured approach works best. Panicked phone calls and angry emails rarely lead to good outcomes.

- Gather Evidence: Collect all relevant documents—the PO, the specification sheet, emails, and photos of the defect. Be sure you are correct about the source of the error.

- Contact Your Sales Rep: Clearly and calmly explain the issue. Provide the evidence you gathered. Frame it as "our" problem. For example, "We have a challenge with the latest shipment. The units have a different handle than specified. How can we solve this together?"

- Propose a Solution: Don’t just present a problem; offer a potential solution. This could be a discount, a rework of the defective units, or a credit on a future order. This shows you are a collaborative partner.

- Escalate If Necessary: If your sales contact cannot resolve the issue, politely ask to speak with their manager or the factory owner. Senior leaders have more authority to approve solutions. A message on WeChat to the boss can often accelerate things.

- Involve a Third Party: If you cannot reach a resolution, a sourcing agent or a third-party inspection company can act as a mediator. They often have deep experience navigating these disputes and can help find a fair compromise.

Remember, the goal is not just to fix one bad shipment but to preserve a valuable long-term relationship. When our clients approach us with respect and a focus on solutions, we are always motivated to find a fair outcome.

Conclusion

Clear, documented, and culturally aware communication is the foundation of successful sourcing. By following these strategies, you can prevent misunderstandings, build stronger supplier relationships, and ensure your air fryers are delivered exactly as you envisioned.